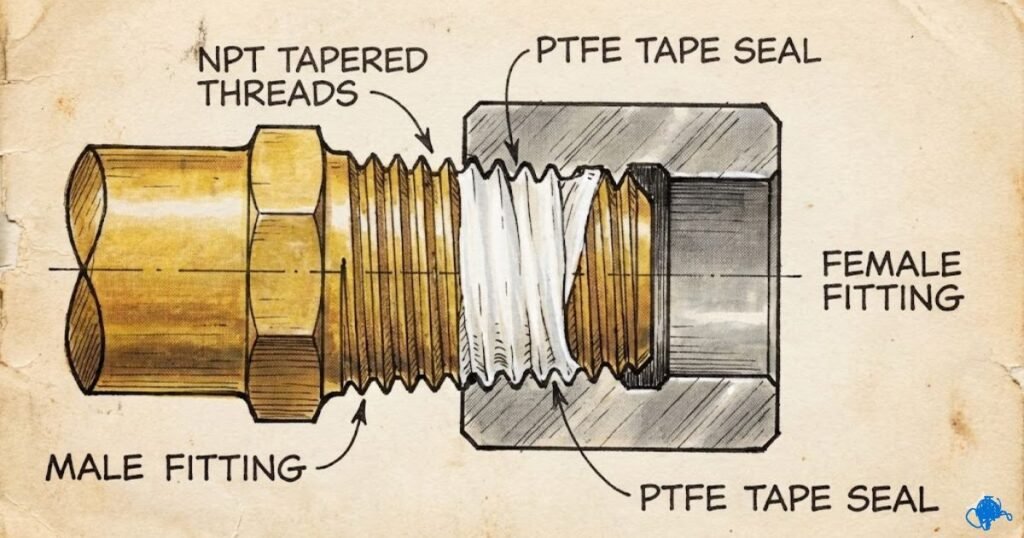

The integrity of a pressurized fluid or gas system is fundamentally dependent upon the reliability of its threaded connections. In the context of North American plumbing, where the National Pipe Thread (NPT) standard is ubiquitous, the application of Polytetrafluoroethylene (PTFE) tape commonly recognized by the DuPont brand name Teflon represents a critical intervention to prevent catastrophic system failure.

The exact count matters because too little tape leaks, and too much tape prevents the metal threads from seating and can cause cross-threading or tape bunching. Practical manufacturer and trade guidance varies a little details, exceptions, and how to apply tape correctly are below.

Why wrap Teflon tape?

PTFE (Teflon) tape is a thin, inert film that fills microscopic gaps between tapered threads, lubricates assembly, and helps form a pressure-tight mechanical seal when the male and female threads are tightened together. It’s not an adhesive; it assists threads to seal rather than replacing proper thread engagement. That’s why wrap count matters: too few wraps leave gaps; too many wraps prevent threads from meshing and can push tape into the flow path. Trade/manufacturer pages call PTFE “suitable for metal and plastic threaded pipe joints” and note temperature/chemical limits for specific formulations. For gas applications you must use gas-rated (yellow) PTFE tape and follow codes the tape type is more important than raw wrap count in gas work.

READ MORE: When to Use Plumber’s Putty vs Silicone Sealant

How Many Times to Wrap Teflon (PTFE) Tape: Recommended Wraps by Pipe Size

The following data provides the standardized wrap requirements for common residential and light industrial applications. These figures assume the use of standard white PTFE tape (approximately 3.5 mil thickness) unless otherwise specified.

| Thread / Pipe Size | Recommended Wraps (Typical) | When to Increase Wraps | Use Teflon? (Yes/No) |

| 1/8″ – 1/4″ (Small Fittings) | 2–3 wraps | Increase if threads are worn or tapered gaps are visible | Yes |

| 3/8″ – 1/2″ (Common Household) | 2–3 wraps | Increase to 3–4 for older brass or worn fittings | Yes |

| 3/4″ – 1″ (Main Supply Lines) | 3–4 wraps | Use 4–5 on loose-fitting or coarse threads | Yes |

| 1.25″ and Up (Large Threads) | 4–5 wraps | Larger gap threads or high-pressure systems | Depends (Consider pipe dope) |

| Gas Lines (Yellow Tape) | 3–5 wraps | Follow local codes—tape type (Yellow) is mandatory | Yes |

| Shower Arms | 3–5 wraps | May require 5–10 or more per specific manual specs | Yes |

For the majority of common 1/2-inch household fittings, such as faucet connections or showerhead arms, a baseline of 2 to 3 wraps is standard. However, as the pipe diameter increases, the surface area and the potential for larger thread voids also expand. For pipes between 3/4-inch and 1-inch, 3 to 4 wraps are typically required to provide sufficient material to fill the thread profile. It is crucial to note that “more” is not always “better”; excessive tape can prevent the threads from engaging deeply enough to trigger the interference fit, potentially resulting in a weaker joint that is prone to blowout under pressure.

The Impact of Material Density and Mil Thickness

The wrap count is inversely proportional to the thickness and density of the tape. Premium, high-density tapes (often marketed as “professional grade” or “MegaTape”) are thicker typically 4 mil (0.1 mm) or more compared to standard economy tapes which may be 3.5 mil or less. When utilizing a high-density tape, 2 wraps may provide the same sealing power as 4 or 5 wraps of a standard-density budget tape. Technical data sheets for premium tapes often specify that a minimum of 3 wraps is sufficient for most NPT fittings up to 2 inches in diameter, provided the threads are within ANSI B1.20.1 tolerances.

Plumber (Teflon) Tape Color-Coding Paradigm

The plumbing industry employs a rigorous color-coding system for PTFE tape to ensure that the material’s density and chemical resistance are appropriately matched to the system’s contents. While all variants consist primarily of virgin PTFE, the pigment serves as a visual indicator of specialized properties and code compliance.

White: Standard Residential Water and Air

White tape is the universal standard for non-critical, low-pressure water and air systems. It is generally a single-density tape that is compatible with most common metals (brass, copper, galvanized steel) and plastics (PVC, ABS). It is the most common choice for DIY repairs involving kitchen faucets and bathroom fixtures.

Yellow: Gas Line Integrity

Yellow tape is manufactured with a higher density and greater thickness (typically 4 mil) specifically to seal joints carrying natural gas, propane, and butane. The smaller molecular structure of these gases requires a more robust barrier than standard white tape can provide. In many U.S. jurisdictions, plumbing codes mandate the use of yellow tape for fuel gas connections to allow inspectors to verify at a glance that the correct material was used.

Pink and Red: High-Pressure and Commercial Water

Pink tape (often packaged in red containers) is a triple-density tape designed for heavy-duty plumbing. It is thicker and stronger than standard white tape, making it suitable for larger pipe diameters (up to 2 inches) and high-pressure water systems. It is frequently found in commercial plumbing where reliability over long-term usage is paramount.

Green: Specialized Oxygen Service

Green PTFE tape is manufactured to be oil- and grease-free. Standard manufacturing processes for PTFE can leave trace amounts of organic lubricants on the tape, which can react explosively in high-pressure, pure oxygen environments. Green tape is mandatory for medical gas lines and welding oxygen systems.

Gray: Anti-Seize for Stainless Steel

Gray tape is enriched with nickel or other anti-seize compounds. It is designed specifically for stainless steel threads, which are highly susceptible to galling. The nickel content provides a protective barrier that allows for disassembly even after years of service in corrosive environments.

READ MORE: How to Plumb a Shower Valve (Step-by-Step DIY Guide)

How to wrap Teflon (PTFE) tape — step-by-step

Follow these steps to get a clean, reliable seal:

- Clean threads. Wipe dirt, oil, old sealant or corrosion from male threads so tape seats in grooves.

- Start one thread back. Begin the tape on the second thread turn from the end (leaving the first thread bare) so loose tape isn’t shoved into the system. Many trade guides and manufacturers recommend this.

- Wrap clockwise (looking at the pipe end). This is crucial clockwise wrapping means the tape will tighten as you screw the fitting on; wrapping counterclockwise causes the tape to bunch and peel. Always wrap in the same direction the fitting will turn during assembly.

- Apply tension and seat tape into grooves. Pull the tape slightly taut and press it into the thread grooves as you wrap so it conforms and doesn’t bunch. Overlapping should be even; avoid bulging.

- Trim and assemble. Tear the tape, smooth the end, thread the fitting on by hand, then snug with wrench; don’t over-tighten overtightening can crack plastic fittings or deform threads. Warn: don’t let loose tape edges get pushed into valves or fixtures.

Quick technique tip: For thin white tape you may want 3 wraps; for thinner industrial tapes or when you need a thicker fill use an extra wrap. For gas, use the thicker yellow tape per manufacturer instructions.

READ MORE: What Does FNPT Mean in Plumbing?

Comparison: Teflon Tape vs Pipe Dope vs Anaerobic Sealants

Teflon Tape (PTFE)

- Pros: clean, easy to apply and remove, inert, works on many metals and plastics. Good for most household threaded joints.

- Cons: too many wraps can prevent thread engagement; shredded tape can contaminate interiors; not ideal as the sole seal in some hydraulic/high-pressure systems.

Pipe Joint Compound (Pipe Dope)

Pipe dope is a non-hardening paste that is brushed onto the threads. It typically contains a mixture of lubricants and fillers such as clay, graphite, or PTFE particles.

- Best For: Large-diameter pipes (over 1.25 inches), gas lines, and high-pressure systems where the paste can more effectively fill large gaps.

- Pros: Highly effective at sealing worn or poorly machined threads; provides excellent lubrication for high-torque assembly.

- Cons: Can be messy to apply; some formulas contain solvents that can degrade certain plastics over time.

Anaerobic Thread Sealants

These are liquid resins that cure into a solid plastic in the absence of oxygen and the presence of metal ions.

- Best For: High-vibration environments and permanent commercial installations where long-term leak prevention is critical.

- Pros: They do not shrink or crack; they provide a high-strength bond that resists loosening.

- Cons: Most expensive option; requires a cure time (up to 24 hours); generally not suitable for plastic threads.

Comparative Feature Matrix

| Feature | PTFE Tape | Pipe Dope (Paste) | Anaerobic Sealant |

| Application Form | Non-adhesive dry film | Brushable thick paste | Liquid / Gel |

| Primary Use | Household water/air lines | Large industrial pipes/gas | High-vibration/Commercial |

| Cleanliness | Very clean; no residue | Messy; requires cleanup | Moderate; precise |

| Cure Time | None (Immediate) | Varies (Some immediate) | 4 to 24 hours |

| Shelf Life | Indefinite | 1–2 years typically | Limited (Approx. 1 year) |

| Difficulty Level | Beginner-friendly | Intermediate | Professional |

Thread Seal Tape (Teflon Tape) How Much

The cost of thread sealants is a marginal expense relative to the total cost of a plumbing project, yet choosing the correct product can save significant time and money in prevented leak damage.

Prices checked on February, 2026. Retail prices are subject to regional fluctuation and bulk availability.

| Product Example | Size / Quantity | Estimated Price (USD) | Retail Source / Type |

| Oatey White PTFE Tape | 1/2 in. x 260 in. | $4.15 – $4.40 | Big-box Home Improvement |

| Oatey Yellow Gas Tape | 1/2 in. x 260 in. | $3.85 – $4.15 | Big-box Home Improvement |

| Harvey Standard White | 1/2 in. x 260 in. | $0.98 | Budget Consumer Grade |

| Blue Monster PTFE Tape | 1/2 in. x 1429 in. | $3.96 – $4.84 | Professional / High Density |

| RectorSeal No. 5 Paste | 1.75 oz. Tube | $4.17 | Pipe Joint Compound |

| Loctite 567 Anaerobic | 50 ml. Tube | $20.00 – $25.00 | Industrial Supply / Specialty |

For most DIY applications, a standard 260-inch roll of white tape is more than sufficient for a full bathroom remodel, costing less than $5.00. However, professionals often opt for high-density rolls like Blue Monster, which offer significantly more tape (1429 inches) for a similar price point, providing a lower cost-per-wrap and superior sealing reliability.

READ MORE: What Is Rough-In Plumbing?

PTFE Tape Troubleshooting & common mistakes

- Too many wraps: If fittings don’t tighten easily or you feel the joint “bottoming out” on tape before threads engage, you’ve used too much. Remove tape and reapply fewer wraps.

- Wrong wrap direction: Wrapping counterclockwise causes tape to bunch and peel when you tighten the fitting leaks follow. Always wrap clockwise.

- Tape entering the system: Start one thread back and avoid loose, trailing edges tape in valves/fixtures can clog screens or damage cartridges.

- Using white tape on gas lines: Don’t. Use yellow gas-rated tape for gas and follow local codes; or hire a licensed pro.

Conclusion

Teflon (PTFE) tape is a cheap, effective tool for sealing threaded pipe joints but count and technique matter. Use the wrap ranges above as your starting point, follow manufacturer instructions for fixtures, and always use the right tape type for gas. If in doubt on high-pressure or unusual systems, choose pipe dope or consult a pro.

5 FAQs

How many wraps of Teflon tape for 1/2 inch pipe?

answer: 2–3 wraps is standard for most 1/2″ household fittings; increase to 3–4 for older/brass or coarse threads. Follow the faucet or fixture manufacturer’s instructions when supplied.

Which direction do you wrap Teflon tape — clockwise or counterclockwise?

Answer: Always wrap clockwise when looking at the pipe end so the tape tightens as you thread the fitting on. Wrapping the wrong way causes bunching and leaks.

Can you use Teflon tape on gas lines?

Answer: Yes — but only yellow gas-rated PTFE tape for gas service. Follow local code and manufacturer guidance; consider hiring a licensed pro for gas work. Tape type matters more than exact wrap count for gas.

How many wraps of Teflon tape for a shower arm?

Answer: Many manufacturers (e.g., Kohler) recommend 2–4 wraps for shower arm/showerhead threads; some trade guides advise 3–6 on certain materials. If the manufacturer gives a count, follow it; otherwise start with 3–4 and test alignment and leak tightness.

Is Teflon tape better than pipe dope?

Answer: Neither is strictly “better” — they serve different needs. Tape is clean and great for most household threaded joints; pipe dope (paste) is often preferable for large/coarse threads, high-pressure systems, or where a more permanent, gap-filling seal is needed. Choose per fitting, pressure, and manufacturer guidance.