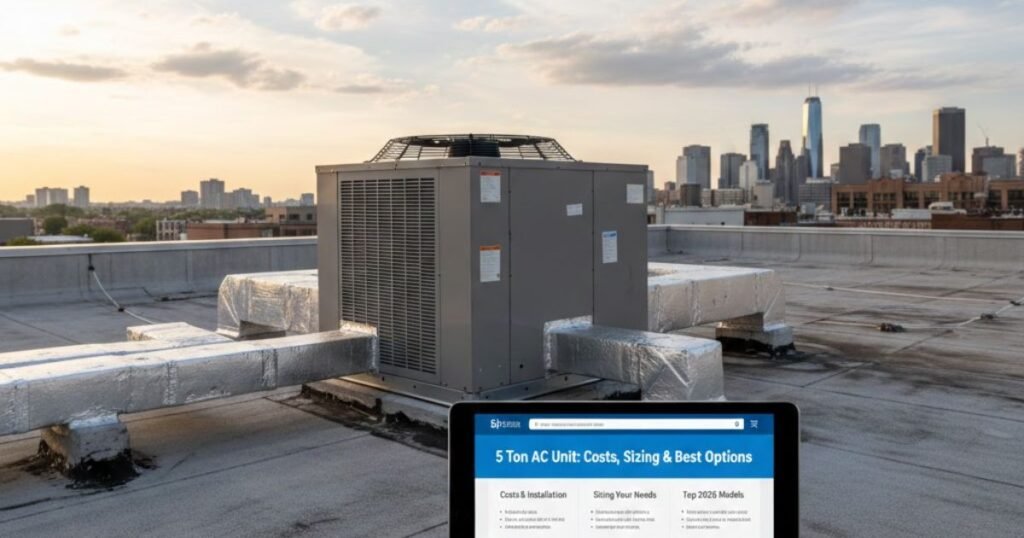

If you’ve landed on this page, you’re probably asking: Is a 5 ton AC unit the right size for my home? Good question. A 5 ton AC unit (that’s 60,000 BTU/h) can cool large or poorly insulated spaces quickly but faster isn’t always better. Oversized systems short-cycle, waste energy, and leave humidity uncontrolled. Undersized systems run constantly and can’t keep up.

This guide walks you through everything homeowners need to know: what a 5 ton Air Conditioner actually is, who generally needs one, realistic cost ranges (equipment and installed), efficiency and SEER basics, duct and electrical implications, plus alternatives like 4 ton ac systems, inverter variable-capacity ac models, and ductless ac options. I’ll also give real-world examples, installer anecdotes, and a contractor checklist so you can confidently request quotes and schedule an in-home Manual J load calculation.

Quick summary

- Typical Home Size Cooled: 2,500–3,500 sq ft (varies by climate and insulation).

- Typical Price Range (Equipment + Install): $7,000–$12,000 nationally; higher in hot climates or with upgrades.

- Pros: Powerful cooling for large spaces; better humidity control in humid areas; long-term energy savings with high SEER models.

- Cons: Higher upfront cost; risk of short cycling if oversized; increased operating costs if not efficient.

What is a 5 ton AC unit?

In HVAC, “tons” describe cooling capacity not weight. One ton equals 12,000 BTU per hour. So a 5 ton AC unit delivers about 60,000 BTU/h at full capacity.

BTU (British Thermal Unit) is the energy needed to raise one pound of water by one degree Fahrenheit. Put simply: more BTUs = more cooling power. But more power doesn’t automatically mean better comfort.

A few related terms you’ll see:

- SEER (Seasonal Energy Efficiency Ratio): Higher SEER means more efficient cooling important for operating cost. Typical modern systems range from mid-14 SEER to high-20s for premium units.

- EER: Instant efficiency measure at a fixed outdoor temp; less used for seasonal comparisons but shows peak performance.

- Single-stage vs. two-stage vs. variable-capacity (inverter): Single-stage runs full blast or off. Two-stage has high/low settings for better part-load efficiency. Variable-capacity modulates output to match load best for comfort & humidity control.

A 5 ton split or packaged central air system is commonly paired with an appropriately sized furnace/air handler and ductwork. Always match components per manufacturer specifications (that’s part of Manual S and good installation practice).

Who needs a 5 ton unit?

A 5 ton unit is not for every large house it’s for specific conditions. Here are typical situations where installers recommend one:

- Square footage & layout: Large 1–2 story homes roughly 2,400–3,200+ sq ft depending on climate, window area, and ceiling height. For two-story homes, the top floor typically needs more cooling, so the whole-house load may push you toward 5 tons.

- Climate: Hot, humid climates (Southeast, deep South, parts of Texas, Florida) often require higher capacity to combat both sensible and latent (humidity) loads.

- High heat gain homes: Lots of south-facing windows, poor insulation, metal roofs, or large sunrooms increase cooling needs.

- High ceilings & open plans: Vaulted ceilings and open-concept designs raise conditioned volume and solar gain.

- Additions or remodeled spaces: If you’ve added a big sunroom or converted attic space without reworking the whole system, a larger condenser may be needed.

Installer anecdotes: many techs say they see homeowners choose larger units because “bigger must be better.” A common correction: oversizing leads to short-cycling the compressor turns off quickly, never running long enough to dehumidify. That leaves your home feeling clammy even if the thermostat reads the target temperature.

Common mistakes that push to oversizing:

- Using square footage as the only rule of thumb.

- Not accounting for shading, window orientation, or attic insulation.

- Buying a system to match an old, undersized unit without a fresh Manual J.

READ MORE: New HVAC System Cost — What It Really Costs to Replace Your Heating & Cooling

How sizing works: Manual J & Manual S explained

Manual J is the industry-standard load calculation that estimates heating and cooling needs for a specific house. It considers:

- Square footage and room-by-room breakdown

- Orientation and window sizes

- Insulation levels (walls, attic, floors)

- Air infiltration (leaks)

- Ceiling heights, occupancy, and internal heat gains (appliances, lighting)

- Local climate data

A Manual J gives the sensible (temperature) and latent (humidity) loads, usually in BTU/h. It tells you how much cooling the house needs at design conditions.

Manual S then helps match equipment to that load selecting condensers and air handlers that can meet the load while maintaining efficiency. Manual S ensures you don’t pick a unit with unsuitable capacity or airflow characteristics.

Why square footage alone is risky: two 2,800 sq ft houses can have wildly different loads one shaded and well-insulated, the other sun-drenched with large glass and poor attic insulation. Manual J sees those differences.

What to demand from contractors:

- A room-by-room Manual J (not just a “rule of thumb” or chart). This is especially important when considering a 5 ton unit.

- A Manual S or equipment selection worksheet showing why a particular model was chosen.

- A ductwork analysis (Manual D) if ducts are undersized or leaky.

If a contractor won’t provide a Manual J, politely move on.

Costs: equipment, installation, ductwork, permits, removal

National ranges (estimates):

- Equipment only (5 ton condenser + coil/air handler): $4,000–$8,000 depending on SEER, brand, and features.

- Installed cost (typical): $8,000–$15,000 — this is the common range for replacing a like-for-like central system with moderate complexity.

- High-efficiency installs (20+ SEER or variable-capacity): $12,000–$22,000 or more.

- Ductwork replacement/major repairs: $2,000–$8,000+ depending on scope.

- Permits, electrical upgrades, and disposal: $200–$1,500 (permits vary widely by locality).

Cost drivers to watch:

- SEER rating: Higher SEER increases equipment cost but reduces operating expense.

- Labor complexity: Long refrigerant lines, difficult rooftop installs, or long runs of duct increase labor.

- Refrigerant type: Newer refrigerants or systems requiring special handling add cost.

- Ductwork: If ducts need resizing (Manual D), cleaning, sealing, or replacement, costs add quickly.

- Electrical: A 5 ton condenser may require a larger breaker, new disconnects, or even a service upgrade.

- Permits & local code: Some municipalities have stricter requirements and higher permit fees.

Real-world example: A suburban 2,800 sq ft home in a warm climate: equipment cost $6,500 (14–16 SEER mid-tier), installation $3,500 (standard single-story access, coil swap), duct sealing $1,200, permits $300 = $11,500 installed.

Assumptions & disclosure: These are national averages. Prices vary by region (urban labor rates higher), by season (summer emergency installs cost more), and by market competition.

Comparison table: 5 ton models & alternatives

| Model / System Type | Cooling Capacity | SEER Range | Estimated Installed Cost Range (USD) | Best for (home size/climate) | Notes / Pros |

| 5 Ton Split — Mid SEER (Generic) | 60,000 BTU/h | 14–16 SEER | $8,000–$12,000 | 2,400–3,000 sq ft; moderate climates | Reliable, lower upfront cost, standard warranty |

| 5 Ton Split — High SEER Variable (Inverter) | 60,000 BTU/h (modulating) | 18–26+ SEER | $12,000–$22,000 | 2,400–3,500 sq ft; hot/humid climates | Better humidity control, energy savings, quieter |

| 5 Ton Packaged Unit | 60,000 BTU/h | 13–17 SEER | $9,000–$14,000 | Homes without basement / attic space | All-in-one unit, easier rooftop install, space saver |

| 4 Ton Split — Comparison | 48,000 BTU/h | 14–20 SEER | $6,500–$11,000 | 1,800–2,500 sq ft; mild climates | Lower upfront cost, less risk of short-cycle if matched properly |

| Ducted Mini-Split (Multi-zone ~5 ton total) | ~60,000 BTU/h total | 16–30 SEER | $10,000–$20,000 | Zoned homes, additions, retrofit without duct rebuild | Great zoning, high efficiency, retrofit-friendly |

| 5 Ton Single-Stage Budget | 60,000 BTU/h | 13–14 SEER | $7,500–$10,500 | Budget conscious homeowners | Lower price, less precise humidity control |

Explanation: The table above shows typical system categories rather than brand-specific models. Use manufacturer specs for exact performance and match to Manual J results. Estimates assume moderate installation complexity and typical regional labor.

READ MORE: Air Conditioning Companies — Compare, Costs & How to Choose

Pros & cons of choosing a 5 ton system

Pros

- Powerful cooling for large or high-load homes.

- Shorter run-times to drop indoor temperature quickly (useful in extreme heat spikes).

- When paired with variable-capacity technology, excellent comfort and humidity control.

Cons

- Oversizing risk: short-cycling hurts humidity control and compressor life.

- Higher upfront cost for equipment and potential duct/electrical upgrades.

- Larger units require more careful matching (airflow, coil sizing) — mistakes are more expensive.

Installer note: Many contractors prefer to right-size and then use zoning or multi-stage equipment to handle fluctuating loads rather than defaulting to a larger single-stage condenser.

Energy efficiency & operating costs

SEER matters. A higher SEER means lower energy consumption for the same cooling effect. For a rough estimate of annual operating cost, consider these points (examples are illustrative):

- A 5 ton unit running in an 80°F average cooling season with 1,000 cooling hours could consume differently depending on SEER. The formula: BTU/h ÷ SEER = Watts (simple conceptual). Real-world calculations require local cooling degree days and electricity rates.

Example estimates (very rough):

- 14 SEER 5 ton: higher electricity use more dollars per month in hot months.

- 20 SEER 5 ton variable capacity: significantly lower operating expense; savings compound over years.

Thermostat & zoning tips:

- Use a programmable or smart thermostat to reduce runtime when no one’s home.

- Consider zoning dampers or a multi-zone ducted approach if different parts of your home have different needs. This helps avoid overconditioning cooler parts of the house and increases comfort.

Humidity control: Oversized single-stage units struggle to remove humidity because they run in short bursts. Variable-capacity units run longer at lower output removing more moisture and improving perceived comfort.

Estimate your cost: To estimate monthly costs, multiply the system’s estimated kW draw by average cooling hours and by your local electricity rate. Ask contractors to provide estimated annual kWh usage for the proposed model.

Installation considerations & timeline

Typical installation steps:

- Site assessment & Manual J — contractor measures home and performs load calc.

- Equipment selection (Manual S) — choose condenser, coil, and air handler.

- Permit pull & scheduling — permits often required; timeline can add a few days to weeks depending on local code office.

- Removal of old equipment — includes reclaiming refrigerant and disposing of old units.

- Ductwork prep or changes — resizing, sealing, or new trunk runs as required.

- Electrical upgrades — install proper breakers, disconnects, and possibly service upgrade.

- Final startup & balancing — airflow verification, refrigerant charge, and homeowner walkthrough.

Typical timeline: 1–5 days for a standard replacement with existing appropriate ducts. More complex installs (new ducts, rooftop placement, or structural work) can take 1–3 weeks.

Contractor checklist to give to homeowners:

- Ask for Manual J, Manual S, and a written scope of work.

- Confirm permit responsibility and who pays fees.

- Verify warranty coverage and what routine maintenance is required to keep it valid.

- Request start-up paperwork with measured airflow (CFM), static pressures, and refrigerant charge verification.

READ MORE: Ducted Air Conditioning: Complete Guide for U.S. Homeowners

Maintenance & lifespan

Typical lifespan: 12–20 years depending on maintenance, climate, usage, and quality of installation.

Routine maintenance recommendations:

- Twice-yearly professional checkups (spring for cooling, fall for heating if combo system).

- Filter changes every 1–3 months depending on filter type and household conditions.

- Duct sealing & inspection every few years or when performance drops.

- Coil cleaning and condensate drain check annually.

Common repairs: compressor replacement (expensive), capacitor and contactor replacement, refrigerant leaks, fan motors, and control board issues.

Warranty expectations: Manufacturers commonly offer 10-year limited warranties on major components, but labor warranties vary by contractor. Keep paperwork and follow recommended maintenance to preserve warranty rights.

Alternatives & when to choose them

4 ton vs 5 ton vs 6 ton

- 4 ton (48,000 BTU/h): Good for many 1,800–2,500 sq ft homes in moderate climates. Less upfront cost and lower risk of oversizing for well-insulated homes.

- 5 ton (60,000 BTU/h): Better for larger volumes, high ceilings, or high heat gain homes (2,400–3,200+ sq ft typical range, climate dependent).

- 6 ton (72,000 BTU/h): Rare for single-family homes unless there are extreme loads think very large open commercial-like spaces or homes with multiple large additions.

Variable-capacity systems (inverter or modulating compressors)

If you’re worried about cycling and humidity, variable-capacity condensers are a great alternative. They adjust output continuously to match load, offering better comfort and energy savings but higher upfront cost.

Ductless / Mini-splits (ducted mini-split or multi-zone)

Ducted mini-splits or multi-zone systems can provide the equivalent of a 5 ton system split across zones. They’re especially useful when ducts are poor or when you want room-by-room control. Advantages: high SEER, retrofit friendliness, and excellent zoning. Consider them if duct replacement costs would be high.

Two-stage systems

A two-stage compressor that runs at 70% capacity most of the time and 100% for peak loads can be a budget-friendly middle ground. It reduces short-cycling compared to single-stage units.

When to choose an alternative:

- Ducts are in poor shape or replacement is prohibitively expensive → consider ductless or a zoned mini-split.

- Humidity control is critical → variable-capacity systems.

- Budget limits → properly sized 4 ton unit might be the better value than a poorly matched 5 ton.

How to choose a contractor & questions to ask

What to verify:

- License & insurance: Confirm the contractor is licensed where required and carries liability and workers’ comp insurance.

- NATE certification: NATE-certified techs have proven HVAC competency.

- References & reviews: Ask for local references and recent jobs similar in size/complexity.

Questions to ask:

- Will you provide a detailed Manual J and Manual S? (Insist on it.)

- Can I see the itemized quote? (Labor, equipment, permits, ductwork shown separately.)

- What is the SEER of the proposed system and the estimated annual energy use?

- Who handles permits and inspections?

- What warranties cover parts and labor, and what maintenance keeps the warranty valid?

- Will you document airflow (CFM) and refrigerant charge at startup?

Red flags: vague quotes, unwillingness to show load calculations, very low bids with no breakdown, or no local references.

READ MORE: HVAC Near Me

Financing & rebates (150–200 words)

Financing options:

- Many contractors offer 0% interest promotional financing for a limited term.

- Home equity, personal loans, or HVAC-specific loans (or PACE where available) are common.

- Compare APRs and total cost — low monthly payments can hide long-term interest costs.

Rebates & incentives:

- Federal, state, and utility rebates sometimes apply to high-efficiency equipment. Check local utility programs and ENERGY STAR incentives.

- Be cautious: rebate eligibility may require specific model numbers, a licensed installer, and pre-approval.

Ask your contractor to help identify available rebates and provide guidance on paperwork but always verify program rules directly with the utility or program administrator.

FAQs

1. How much does a 5 ton AC unit cost installed?

A 5 ton AC unit installed typically ranges from about $8,000 to $15,000 for a standard replacement, with high-efficiency or complex installs reaching $20,000+. Equipment-only prices can be $4,000–$8,000. Costs depend on SEER, labor rates, ductwork condition, refrigerant requirements, and local permit fees. Ask for itemized quotes and get at least 2–3 bids to compare.

2. What size house does a 5 ton AC cool?

A 5 ton AC commonly suits homes roughly 2,400–3,200+ sq ft, but this varies widely with climate, insulation, window area, ceiling height, and sun exposure. Two homes of the same square footage can need different capacities; that’s why Manual J room-by-room calculations are essential.

3. Is a 5 ton AC too big for my house?

It might be. If your home is well insulated, shaded, or under ~2,200–2,400 sq ft in a moderate climate, a 5 ton unit can be oversized and cause short-cycling. If a contractor recommends 5 tons without a Manual J, ask for the calculation or get a second opinion.

4. What SEER should I get for a 5 ton AC unit?

Minimum SEER varies by region, but modern replacements typically start at mid-teens (14–16 SEER). For better long-term savings and comfort, consider 16–20+ SEER or variable-capacity systems if your budget allows. Higher SEER reduces energy bills but increases upfront cost calculate payback based on local electricity rates.

5. How much energy does a 5 ton AC use per month?

Energy use depends on SEER, hours of operation, thermostat setpoint, and climate. Roughly, a 5 ton unit at full output draws several kilowatts; multiply estimated kW by cooling hours and your electricity rate. For a contractor estimate, ask for expected annual kWh usage for the proposed model and local cooling hours.

Conclusion

If you’re debating a 5 ton AC unit, the smart next step is a Manual J load calculation and an in-home survey. Get 2–3 itemized quotes from NATE-certified contractors who will show Manual J and Manual S workups, explain ductwork needs, and document startup airflow and refrigerant charge.

A properly sized system (not simply the biggest one available) will save you money, improve comfort, and protect humidity control. Ready to move forward? Ask your preferred contractor for a room-by-room Manual J and a written scope or get back to me and I’ll help you draft the right questions to send to local installers.