A heat exchanger is a device that enables efficient thermal energy transfer between two fluids (liquid or gas) without mixing them. By moving heat from a hot stream to a colder one, heat exchangers play a crucial role in heating and cooling applications across industry and residential settings. They are found in everything from car radiators and home HVAC (heating, ventilation, and air conditioning) units to large power plant condensers and chemical processing systems.

Using a heat exchanger often means reusing waste heat instead of generating new heating or cooling energy, which saves fuel and electricity. In industrial operations, for example, exhaust or boiler heat can be captured by a heat exchanger and used to preheat incoming process fluids, cutting energy consumption and emissions.

Heat exchangers are vital because heat accounts for a large part of industrial energy use, and recovering even a portion of it can hugely improve efficiency. For instance, capturing waste heat in a refinery or power plant can reduce overall fuel use and greenhouse gas emissions. In homes and buildings, air conditioners and furnaces all use heat exchangers to move thermal energy between coils and air or water.

This guide will explore their types (e.g. shell-and-tube, plate, finned, etc.) and how they operate, materials used, performance measures, common applications across industries, maintenance best practices, and latest innovations. By the end, you’ll have a full picture of heat exchanger technology and practical tips for selecting and caring for these critical devices.

Types of Heat Exchangers

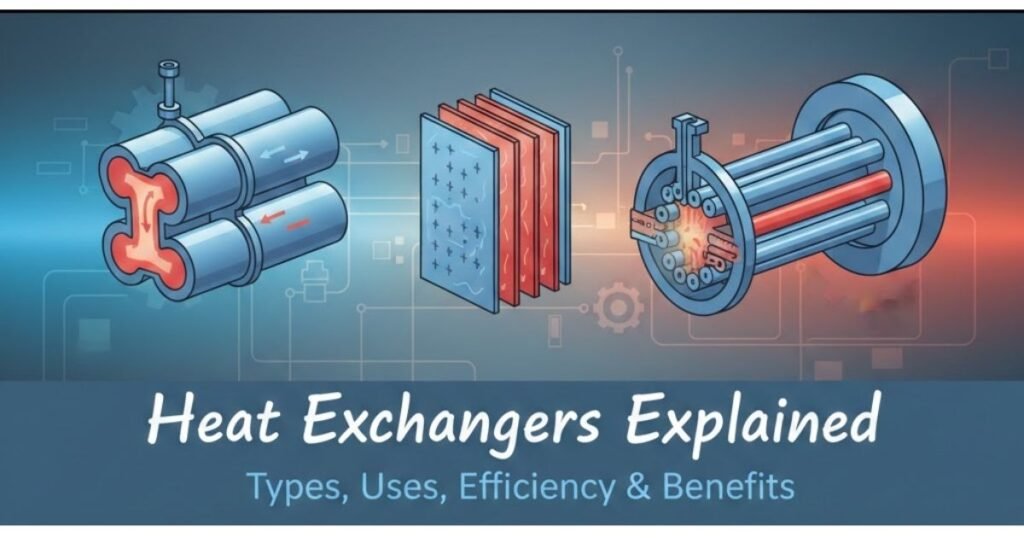

Heat exchangers come in many shapes and sizes, but most fall into a few well-known categories. Each type has characteristics that make it better suited for particular applications.

1. Shell-and-Tube Heat Exchangers

Overview: A bundle of tubes housed inside a cylindrical shell. One fluid runs through the tubes; the other flows around the outside of the tubes inside the shell.

Working principle: Crossflow or counterflow arrangements with baffles to direct shell-side flow and increase turbulence for better heat transfer.

Key applications: Power plants, petrochemical plants, large-scale process cooling, oil refineries.

Strengths: Strong mechanical design for high pressures and temperatures; scalable to very large capacities; robust for fouling-prone fluids.

Limitations: Larger footprint relative to plate designs; higher material usage; may have lower heat-transfer coefficient per unit volume than good plate exchangers.

2. Plate Heat Exchangers (Gasketed)

Overview: Thin, corrugated metal plates stacked to create narrow channels for fluids. Gaskets seal the plate edges and direct fluid flow in alternating channels.

Working principle: Alternating channels create counterflow or crossflow paths; corrugation increases turbulence and heat transfer surface area.

Key applications: HVAC, food and beverage pasteurization, light industrial processes.

Strengths: High heat transfer efficiency per volume; easy to disassemble for cleaning or to change capacity (add/remove plates).

Limitations: Gasket compatibility limits maximum temperature/pressure and some aggressive fluids.

3. Brazed Plate Heat Exchangers (BPHE)

Overview: Like plate heat exchangers but plates are brazed (often copper) instead of gasketed, making them compact and leak-free.

Key applications: Refrigeration systems, hydronic heating/cooling, compact industrial systems.

Strengths: Extremely compact, high heat transfer coefficients, reliable seals, suitable for higher pressures than gasketed plates.

Limitations: Not serviceable (plates cannot be separated); brazed joints may limit some fluid chemistries or maximum temperatures.

4. Finned Tube (Air-cooled) Heat Exchangers

Overview: Tubes carry fluid while fins increase air-side surface area; an external fan forces air over fins.

Key applications: Condensers, cooling towers, air-cooled heat rejection for remote sites.

Strengths: No external water needed; effective where water is scarce; compact horizontal layout.

Limitations: Air-side heat transfer is inherently lower than liquid-liquid; performance drops at high ambient temperatures; susceptible to fouling from dust.

5. Air-cooled (Standalone) Heat Exchangers

Overview: Entire heat rejection system using ambient air — includes finned tube bundles or coil banks, often with fans.

Key applications: Oil & gas, remote plant cooling, engine cooling.

Strengths & Limitations: Similar to finned-tube advantages and constraints.

6. Double-Pipe (Coaxial) Heat Exchangers

Overview: One pipe inside another; simple counterflow or parallel flow arrangement.

Key applications: Small flow rates, pilot plants, high-temperature differentials.

Strengths: Simple, low cost, easy to fabricate; ideal for small duties.

Limitations: Limited heat transfer area per footprint; not practical for large capacities.

(Tip: Many industrial systems use hybrid arrangements: shell-and-tube for main duty plus compact plate exchangers for heat recovery or secondary loops.)

READ MORE: New Boilers Buying Guide for Homes and Businesses

Materials Used

The choice of construction material greatly affects performance, cost, and longevity. Common materials include stainless steel, copper and copper alloys, aluminum, titanium, carbon steel, and high-nickel alloys. Each has advantages and limitations:

1. Stainless Steel

Pros: Excellent corrosion resistance, sanitary surfaces for food/pharma, suitable over a broad temperature range.

Cons: More expensive than carbon steel; some grades less thermally conductive than copper.

Best for: Food & beverage, pharmaceutical, potable water, many corrosive environments.

2. Copper and Copper Alloys

Pros: High thermal conductivity, commonly used in brazed plate and residential HVAC.

Cons: Susceptible to some corrosive fluids and ammonia; not ideal for chloride-rich environments.

Best for: HVAC, refrigeration, domestic water systems.

3. Aluminum

Pros: Lightweight and good thermal conductivity for air-cooled units and automotive radiators.

Cons: Less corrosion resistant in some environments; limited use with highly alkaline or saline fluids.

Best for: Automotive, air-cooled radiators, lightweight heat exchangers.

4. Titanium

Pros: Exceptional corrosion resistance (especially to seawater and aggressive chemicals), good strength-to-weight ratio.

Cons: High cost.

Best for: Marine, desalination, aggressive chemical processes.

5. Carbon Steel (with appropriate coatings)

Pros: Low cost, strong for high-pressure shell-and-tube designs.

Cons: Rust-prone if not protected; not suitable for corrosive fluids without linings.

Best for: Oil and gas, some industrial steam duties where fluids are non-corrosive.

Choosing materials: Consider fluid chemistry, temperature, pressure, regulations (e.g., FDA for food), and lifecycle cost: sometimes a pricier alloy saves money long-term by avoiding corrosion and downtime.

How Heat Exchangers Work

At its core, a heat exchanger transfers thermal energy from a hotter fluid to a cooler one, relying on conduction and convection across a separating wall.

Heat transfer modes

- Conduction: Heat flows through a solid wall (plate or tube) from the hot side to the cold side. The rate depends on material thermal conductivity and wall thickness.

- Convection: Heat transfer between a fluid and a surface due to fluid motion. Convection coefficients depend on flow regime (laminar vs turbulent), fluid properties, and surface roughness.

Key principles

- Counterflow vs Parallel flow: Counterflow arrangements (fluids moving in opposite directions) maintain a higher average temperature differential across the exchanger and generally yield better thermal performance than parallel flow.

- Log Mean Temperature Difference (LMTD): A standard engineering metric estimating the effective mean temperature difference driving heat transfer in steady-state exchangers.

- Heat transfer coefficient (U): Combined measure including conduction through wall and convective resistances on both sides; higher U means more compact exchangers.

Factors affecting efficiency

- Surface area: More area increases heat transfer. Plate exchangers concentrate area into compact envelopes.

- Flow pattern and turbulence: Turbulence raises the convective heat transfer coefficient but also increases pressure drop.

- Fouling: Deposition of scale, biofilm, or particulates reduces thermal transfer and raises pressure drop a major practical efficiency killer.

- Temperature approach: The closer the output temperatures are to each other (small approach), the more efficient the exchanger is for recovery duties, but often at the cost of increased area and pressure drop.

- Pressure drop trade-offs: Larger pressure drops can improve heat transfer but increase pumping power and operational cost. Proper design balances heat transfer and pumping energy.

Common issues: fouling and corrosion

- Fouling: Build-up of deposits on heat transfer surfaces reduces thermal conductivity and flow area. Mitigation includes selecting low-fouling designs, chemical dosing, filtration, and routine cleaning.

- Corrosion: Chemical attack on material leading to leaks and failure. Choose materials compatible with fluids and maintain protective measures (coatings, inhibitors, cathodic protection).

Practical engineering note

Designers must balance thermal performance (U and area) against hydraulics (pressure drop) and operational concerns (cleanability and material compatibility). For example, plate exchangers give high U and small footprint but can be more susceptible to fouling with dirty fluids compared to shell-and-tube designs that handle fouling more robustly.

READ MORE:HVAC Near Me

Efficiency and Performance Metrics

Understanding metrics helps you compare models and measure gains from maintenance or upgrades.

Heat Transfer Coefficient (U)

The overall thermal conductance (W/m²·K) reflects how readily heat crosses the exchanger. U depends on:

- Material thermal conductivity

- Convective coefficients of each fluid (influenced by flow velocity and properties)

- Wall thickness

A higher U means less surface area needed for a given duty, which often translates to smaller, cheaper units.

Pressure Drop

Measured as the loss of fluid energy across the exchanger (psi or kPa). Pressure drops increase pumping energy and can limit achievable flow rates. Designers aim to minimize drop while maintaining sufficient turbulence for heat transfer.

Effectiveness (ε)

The ratio of actual heat transfer to maximum possible transfer for given inlet conditions. High-effectiveness units extract more heat per unit flow and are particularly valuable in heat recovery systems.

NTU (Number of Transfer Units)

NTU is a dimensionless metric used with effectiveness to design and rate exchangers. It combines U, area, and flow capacity to predict performance.

Energy Savings Potential

Upgrading to a more efficient exchanger or recovering waste heat can significantly lower fuel or electrical consumption. Real-world savings depend on duty cycles, temperature differences, and system operating hours.

Maintenance Requirements

Performance will degrade if fouling or leaks occur. Maintenance metrics include mean time between cleanings, leak rates, and downtime for servicing.

Heat Exchanger Market Comparison Table — Popular Brands & Models

Below is a representative comparison of several leading heat exchanger brands and models. Note that exact prices and specs vary by model and application, so the table gives typical ranges and focus areas:

| Brand / Model | Price Range | Efficiency | Materials | Capacity (Thermal) | Warranty | Typical Applications |

| Alfa Laval (Plate) | $$$–$$$$ | Very high (compact, up to ~90% effectiveness) | Stainless steel plates | Up to several MW | ~3 years (AHRI-certified models) | HVAC, food/bev, dairy, refrigeration |

| Kelvion (Shell & Air) | $$–$$$$ | High (industrial-grade) | Carbon steel, SS shells | Large (industrial to ultra-large) | ~1–3 years (varies) | Power plants, HVAC, chemical, oil & gas |

| SWEP (Brazed Plate) | $$–$$$ | Very high (brazed plates, up to 90% smaller footprint) | Stainless steel | Up to several MW | 2–3 years (typical) | HVAC (chillers, heat pumps), refrigeration, district heating |

| API Heat Transfer | $$–$$$$ | High (compact brazed & plate) | Stainless, copper | Multiple MW (brazed plate, shell/tube) | ~3 years (common) | Petrochemical, HVAC, refrigeration |

| Tranter | $$$–$$$$ | High (plate & shell models) | Stainless steel & alloys | Up to MW scale | ~2–3 years | Heavy industry, power generation |

Sources: Industry reports and manufacturer data. This table is illustrative. For example, Alfa Laval is known for its wide range of gasketed plate exchangers (with AHRI-certified performance and a 3-year warranty). Kelvion offers everything from shell-and-tube bundles to large air-cooled condensers for data centers and industrial plants. SWEP specializes in brazed plate exchangers that deliver exceptional efficiency in a tiny package. API Heat Transfer, Tranter, and others provide robust designs for chemical, food, and power applications. When comparing, consider not just unit cost but also material suitability, thermal duty, pressure rating, and after-sales service. Often, vendors tailor a quote to your exact needs.

READ MORE: Electric Company Near Me

- High Thermal Efficiency: Turbulent-flow design moves the two media in opposite directions and creates strong turbulences…

- Energy Optimized: This heat exchanger stainless can heat water to the preset temperature, which is super energy-saving w…

- Robust Construction: This 40 plate heat exchanger features 316L stainless steel sheets, which are brazed together at the…

Applications Across Industries

Heat exchangers are ubiquitous in modern industry and infrastructure. Key application areas include:

- HVAC and Building Systems: In heating and air conditioning, heat exchangers transfer heat between refrigerant and air (in condensers/evaporators), or between boiler/chiller loops and water. Nearly every HVAC system (from residential furnaces to large commercial chillers) uses plate or finned-tube exchangers. For example, a building air handler might have finned coils where a glycol-water loop exchanges heat with passing air. According to market analysis, the HVAC and refrigeration sector accounts for about 17% of global heat exchanger demand. This reflects the massive scale of climate control systems driven by urbanization and climate-change-related cooling needs.

- Power Generation: Power plants rely heavily on shell-and-tube exchangers. They serve as condensers (cooling steam back to water), feedwater heaters (using turbine exhaust steam to preheat boiler feedwater), cooling water exchangers for turbine seals and oils, and waste heat recovery units. In 2024, power generation was the single largest market segment (over 23% share) for shell-and-tube exchangers. Nuclear, coal, natural gas, and even renewable plants (like solar thermal) all use large coolers. Air-cooled condensers are common in desert power plants where water is scarce.

- Chemical and Petrochemical Processing: Chemical reactors, distillation columns, and heat recovery networks all use exchangers. The chemical industry was roughly tied with power generation in shell-and-tube demand (~20–23%). In refineries and petrochem plants, exchangers heat crude oil for distillation, recover heat from hot process streams, and inter-convert temperature levels. Specialized exchangers (e.g. with titanium tubes) handle corrosive acids or chloride-laden streams. Plate exchangers are also used for heat recovery and batch heating in chemical plants.

- Food, Beverage, and Pharmaceutical: These industries need precise temperature control (pasteurization, sterilization, brewing). Plate heat exchangers are very common because they can be cleaned (CIP) and sanitized easily. Dairy pasteurizers, for example, use a series of plate exchangers to heat milk to pasteurization temp and then cool it, all in one compact skid. According to one report, food & beverage applications account for about 8% of heat exchanger market share. Large fermenters or blenders often use jacketed reactors (a form of heat exchanger) or plate units. Hygienic design and corrosion resistance (stainless steel) are critical here.

- Oil & Gas Industry: Upstream and downstream operations both use heat exchangers extensively. In oil production, sand-laden crude often must be heated to reduce viscosity; gas wells may use exchangers to cool gas before compression. Offshore rigs use finned-tube coolers for hydraulic oil and air compressors. In refining (downstream), reactors, fractionators, and fuel gas conditioning all involve heat exchangers. Because of sulfur and salt in some streams, material selection (like clad steels or alloys) is important.

- Marine and Automotive: Ships and offshore platforms use shell-and-tube and plate exchangers for engine cooling (oil, jacket water coolers), cargo heating, and living quarter HVAC. Marine heat exchangers often use seawater on one side, requiring titanium or brass tubes to resist corrosion. In automotive, radiators and oil coolers are basically finned-tube heat exchangers (aluminum). New electric vehicles use compact liquid-to-liquid exchangers to manage battery and cabin heating.

- Renewables and Sustainability: Emerging areas like solar thermal energy and geothermal also use heat exchangers. For example, solar collectors heat a fluid that goes through an exchanger to heat domestic water or drive turbines. Waste heat recovery in industrial processes (e.g. exhaust gases run through heat recovery exchangers) is another growth area, allowing industries to reuse energy that would otherwise be lost.

In summary, industrial heat exchangers are found wherever temperature control is needed. Power generation, petrochemicals, and HVAC dominate demand, but nearly every manufacturing sector from paper mills to semiconductors relies on them. The specific exchanger design (material, type, size) depends on the application’s temperature, pressure, and fluid properties. For instance, HVAC might use brazed plate exchangers (for compactness), while a coal-fired plant uses giant shell-and-tubes. The table in the previous section highlights how different vendors cater to different niches.

Maintenance and Lifespan

Good maintenance extends operational life and preserves efficiency.

Best practices for cleaning

- Plate units (gasketed): Disassemble for mechanical cleaning and gasket inspection when fouling is heavy; pressure wash and chemical cleaning for scale.

- Brazed plates: Not serviceable; use filtration and water treatment upstream to minimize fouling.

- Shell-and-tube: Use tube-side chemical cleaning (CIP), mechanical tube cleaning with brushes or pigs, or hydroblasting where appropriate.

Monitoring & condition checks

- Monitor pressure drop and outlet temperatures: rising pressure drop or declining thermal capacity indicates fouling.

- Inspect for leaks and corrosion during scheduled shutdowns.

- Use water treatment and filters to reduce particulate and scaling agents.

Extending lifespan

- Choose the right material for the service to prevent corrosion

- Implement proactive water/chemical treatment and filtration.

- Design for cleanability and allow space for disassembly if servicing is expected.

- Keep spare gaskets and maintain a log of operating parameters and maintenance actions.

Safety considerations

- Isolate and depressurize before service; hot fluid hazards demand lock-out / tag-out procedures.

- For exchangers handling hazardous fluids, use secondary containment and leak detection.

- Follow manufacturer torque and reassembly guidelines to avoid gasket failure and leaks.

Typical lifespan varies widely: well-maintained industrial exchangers can last decades, while compact brazed units used intensively may be replaced after 10–15 years.

When selecting a heat exchanger for a specific need, consider the following tips:

- Determine Duty and Flow Rates: Calculate the required heat duty (kW or Btu/hr) and the fluid flow rates and inlet/outlet temperatures. Use these to size the exchanger (often with vendor software or formulas).

- Match the Type to the Application: For very large or high-pressure duties (power plants, petrochemical), shell-and-tube or plate-and-shell designs are common. For compact needs (HVAC units, heat pumps), brazed or gasketed plates may be best. Air-cooled units are chosen when water cooling isn’t available.

- Choose the Material: Ensure fluid compatibility. For example, choose stainless steel or titanium for corrosive sea water, copper for clean water/glycol, aluminum for low-pressure HVAC, etc. Refer to material data on conductivity and corrosion as in Materials Used.

- Pressure and Temperature Limits: Verify the exchanger can handle your system’s pressures and temperatures. Some designs (e.g. gasketed plates) have lower pressure ratings than welded shell units.

- Efficiency and Footprint: Consider if space is limited. Brazed plate exchangers, for instance, offer 90% smaller size by weight than equivalent shell-and-tube. Calculate estimated heat transfer to compare different models.

- Maintenance and Access: If frequent cleaning is expected (e.g. food processing), a design that opens easily (plate frame) may be preferred. For dirty fluids, consider a removable-tube shell exchanger that can be mechanically cleaned.

- Warranties and Service: Check manufacturer warranties (e.g. 2–3 years is common) and availability of spare parts. Established vendors usually offer better support.

Finally, it can be valuable to consult with experts or manufacturers. Provide them with as much process information as possible; they can run thermal calculations (often using NTU or LMTD methods) to recommend the optimal exchanger. Many companies offer digital selection tools or field studies to fine-tune the design. Remember that the cheapest upfront cost may not be the best deal if it leads to higher energy use or more maintenance later. A high-quality, efficient exchanger can pay for itself via lower energy bills and longer service life.

- Made of high quality full aluminum construction

- Core Size:258mm*485mm*40mm

- Over Size: 293mm*608mm*54mm

Latest Innovations & Trends

Modern developments are pushing heat exchangers toward higher efficiency, lower footprint, and smarter operation.

Compact, high-efficiency designs

Microchannel, printed-circuit, and high-intensity plate patterns squeeze more surface area into smaller volumes beneficial where space and weight are at a premium (data centers, mobile platforms).

Smart heat exchangers & IoT integration

Sensors for differential temperature, flow, and pressure combined with predictive analytics let operators schedule cleaning before performance drops, optimize pump energy, and detect leaks early.

Materials and additive manufacturing

3D printing and advanced brazing techniques enable novel internal geometries that maximize turbulence and heat transfer while minimizing pressure drop.

Sustainability & energy recovery

More plants adopt heat-recovery networks using efficient compact exchangers to reclaim low-grade waste heat, reducing fuel consumption and greenhouse gas emissions.

(Manufacturers such as Alfa Laval, SWEP, Kelvion, and SPX Flow are continuously developing higher-efficiency plate patterns and sensor-ready modules for modern systems.)

Conclusion

Heat exchangers are essential components in nearly every industry that requires heating or cooling. We have seen that they come in various types (shell-and-tube, plate, finned, etc.), each with its own advantages and applications. They operate on the principles of thermal conduction and convection, and their effectiveness depends on design choices like flow arrangement, surface area, and material. Materials range from copper and aluminum (for high conductivity) to stainless steels and exotic alloys (for corrosion resistance). The right material and type must match the working fluids and conditions. Key performance metrics include the overall heat transfer coefficient (U), pressure drop, and ultimately energy recovery potential. High-efficiency exchangers can recover waste heat and significantly cut fuel and cooling costs.

FAQ

Q1: What is a heat exchanger and why is it important?

A heat exchanger is a device for transferring heat between two fluids without mixing them. It’s important because it allows efficient heating or cooling in processes. For example, it can recover waste heat from exhaust to preheat incoming fluids, saving fuel and reducing emissions. Heat exchangers are used everywhere from car radiators and home furnaces to power plants and chemical plants enabling energy savings and process control.

Q2: What are the main types of heat exchangers?

The main types include shell-and-tube, plate (plate-and-frame), finned-tube, air-cooled, and double-pipe exchangers. Each has a different geometry: shell-and-tube uses tubes inside a larger shell, plate exchangers use stacks of corrugated plates, finned exchangers have extended fins, and double-pipe is simply one tube inside another. The choice depends on factors like space, pressure, temperature, and fluid type.

Q3: How do shell-and-tube and plate exchangers compare?

Shell-and-tube exchangers are heavy-duty and handle high pressure/temperature; they consist of tubes inside a sealed shell. Plate exchangers are much more compact, using stacks of metal plates with gaskets. Plate units have higher heat transfer per volume and are easier to clean, but usually have lower pressure limits. In terms of “plate vs shell and tube,” plates are favored for efficiency and footprint (e.g. in HVAC), whereas shell-and-tube is used for high-capacity industrial tasks. The best choice depends on your specific application requirements.

Q4: Why do heat exchangers get fouled and how can it be prevented?

Fouling occurs when materials (scale, sediment, microbes, corrosion products) deposit on the heat transfer surfaces. This insulating layer drastically reduces heat transfer and raises pressure drop. Common causes are hard water (mineral scaling), biological growth in warm water, and rust from corrosion. To prevent fouling, operators can filter incoming fluids, add chemical inhibitors (for scale or biofouling), and maintain proper water chemistry. Regular cleaning (CIP or manual) is also crucial to remove any deposits before they build up too much.

Q5: How often should a heat exchanger be cleaned or inspected?

It depends on usage and fluid cleanliness. A common practice is to do visual or instrumental checks daily/weekly (looking at temperatures, pressures, flow rates), quarterly inspections for buildup, and at least annual cleaning of plates or tube bundles. Many industries use a maintenance schedule (daily monitors, quarterly checks, annual CIP, 3–5 year overhaul) to stay ahead of issues. If performance (heat transfer or flow) drops noticeably, immediate cleaning is warranted.

Q6: What heat exchanger materials are best for corrosive fluids?

For corrosive fluids, materials like titanium, high-nickel alloys (Inconel, Hastelloy), or high-grade stainless steels (duplex/316L) are used. Titanium is extremely resistant to seawater and chloride, making it ideal for marine and desalination use. Nickel alloys withstand strong acids. Stainless steel works for mildly corrosive fluids. Always consult corrosion tables or specialists when selecting material for aggressive chemicals.

Q7: What does heat exchanger “efficiency” mean in practice?

Efficiency can mean different things: one measure is how closely the outlet temperature approaches ideal exchange (effectiveness). A well-designed counterflow exchanger can reach over 90% effectiveness. In practical terms, efficiency is often about energy savings: how much of the available heat difference is actually transferred. High efficiency means less wasted heat and lower operating costs. Using a heat exchanger is considered efficient when it significantly reduces the need for separate heating/cooling equipment.

Q8: How do I choose the right heat exchanger for my application?

First, calculate your heat load and flow requirements. Then consider space and layout: do you have room for a large shell-and-tube or prefer a compact plate? Check the fluids: what materials can handle them safely? Consider pressure and temperature – some types have limits. Review energy efficiency versus pump power (pressure drop). Finally, get quotes from reputable manufacturers who can suggest models. Many companies offer software or engineering support to ensure you get an exchanger optimized for your thermal duty and budget.

Each heat exchanger should also be sized to provide the needed safety margin and ease of maintenance. Don’t hesitate to reach out to vendors or consultants: they can run the detailed calculations (using LMTD or NTU methods) and ensure your choice meets performance goals. Proper selection and upkeep will maximize reliability, efficiency, and energy savings.

Sources: Authoritative engineering and industry publications were used to compile this guide, including textbooks and manufacturer data. Each section’s facts are backed by the cited references above.